Product Category

Kale Balata Social Media

Word Cloud

Kale Balata

Kaleu

Disk Fren Balatası

Balata

Fren Diski

Kampanalı Fren Balatası

Photos

WHAT WE EXPECT FROM THE BRAKE PAD

Security

Comfort

Economy

SECURITY

Brake Pad friction coefficient that provides the expected internal brake factor. Stable coefficient of friction.

During Total Braking

In Cold Braking

During Hot Braking

After Heat Braking

Braking with Variable Brake Pressure

Variable Speed Braking

Fast and good surface adjustment.

No Expansion.

Shear Force Resistance.

It does not burn, it can easily throw dirt, rust and dust.

CONFORT

Low pedal force.

Not making a sound.

Does not pollute the environment.

Does not smell.

ECONOMY

Less lining wear.

Low disc or drum wear.

Less weight loss in these parts.

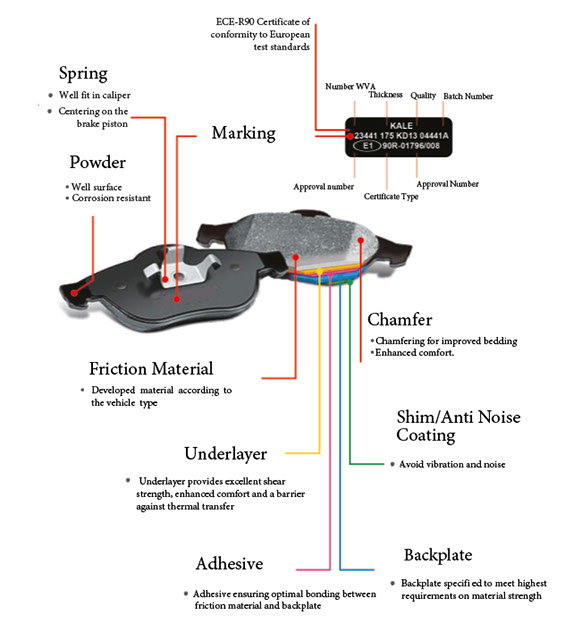

Technical information

Brake pads are used as wheel brakes in vehicles. These brakes, which are generally attached directly to the wheel, perform two main functions.

Establishing the braking torque.

Realization of energy change.

(Conversion of kinetic or potential energy into heat energy and disposal of this heat.) The brake linings of the brakes, which are divided into two types as drum and disc, are also grouped under two groups.

When the brake pedal is pressed, the pressure created by the hydraulic, pneumatic or hydro pneumatic system is transmitted to the brake cylinder.

With the pressure force applied by the brake cylinder to the pads with the help of its pistons, a friction occurs between the pad and the disc / drum, which causes the vehicle to slow down or stop.

The performance of a lining can be evaluated primarily by the friction it creates with the disc or drum, in other words the friction coefficient (µ).

If the friction coefficient is higher than desired, the wheels will be blocked at lower pedal forces (brake pressures), and a low will cause the braking distance to be longer. In both cases, it may cause danger depending on the conditions of the moment. Therefore, while developing the lining, the first target is to provide a lining with a suitable friction coefficient for the vehicle.

How is the expected friction coefficient determined from the brake pad?

The brake force distributions in the vehicle are created with the calculations, using some technical data about the vehicle and the internal brake factor C * that meets the conditions closest to the ideal curve is determined.

Internal braking factor C *

It is the ratio of environmental forces to thrust force. In other words, the internal brake factor determines the braking torque, deceleration or stopping distance predicted by the vehicle manufacturer for any brake pressure. The internal brake factor will also determine the friction coefficient that the vehicle manufacturer expects from the pad.

The relationship between the criteria we expect from the lining should be very well established and it should not be forgotten that one expectation may have a negative effect on the other.

Evaluation to be made by taking into account a single feature of the pad will not be very healthy. For this reason, the pad should be evaluated by considering all the criteria.

Another issue that should not be forgotten is that the lining is only one of the parts in the brake system and the problems and usage conditions caused by other parts in the system (disc-drum surface, shoes, brake cylinders, bellows, s-cam, etc.) It will also negatively affect our expectations in time.

We are Kale, You are safe!

Kale Balata A.S was established in 1976 in Istanbul-Maslak to produce disc brakes pads and brake lining. In order to meet customer expectations and requirements in a timely and complete manner, it moved to new facility in Gebze-Kocaeli, 12000 m2 closed with a total area of 16000 m2.

CONTACT

Adress

Cumhuriyet Mah. İstanbul Cad. No:3 41400

Gebze /Kocaeli - Türkiye

Phone

+90 262 744 03 86 pbx

+90 262 744 66 18

Fax

+90 262 744 03 89

info@kalebalata.com

kale@kalebalata.com

Copyright © 2021 - All rights reserved

İnformative text and cookie policy